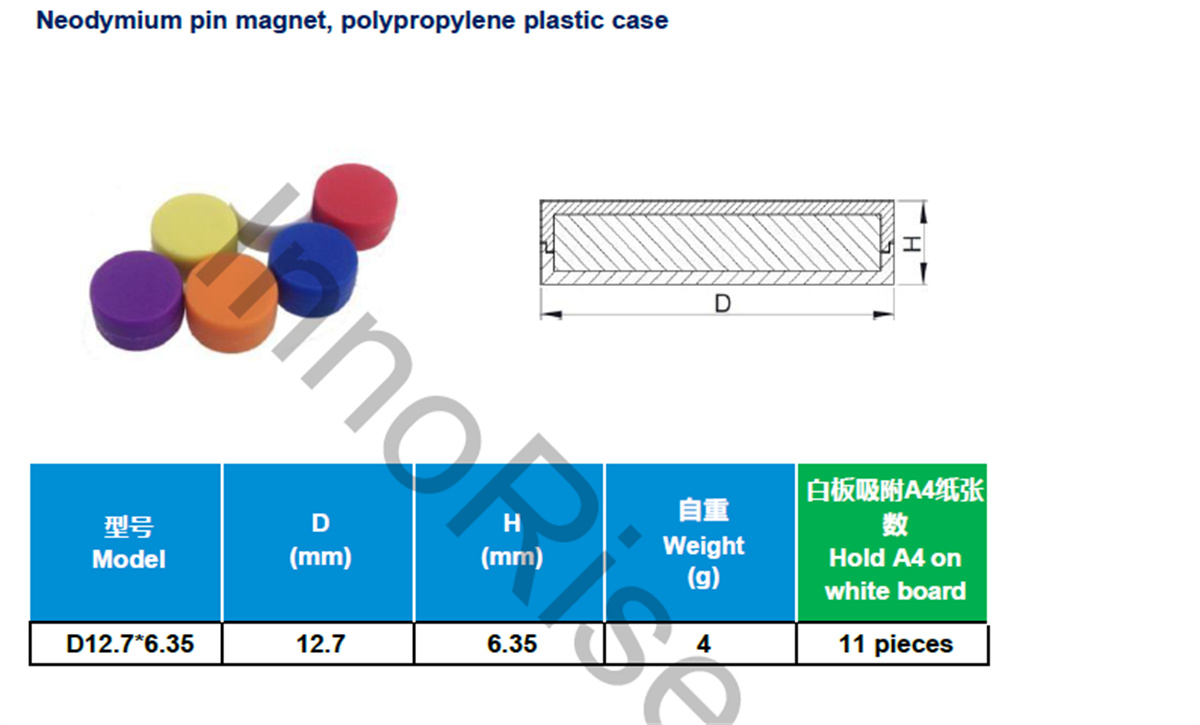

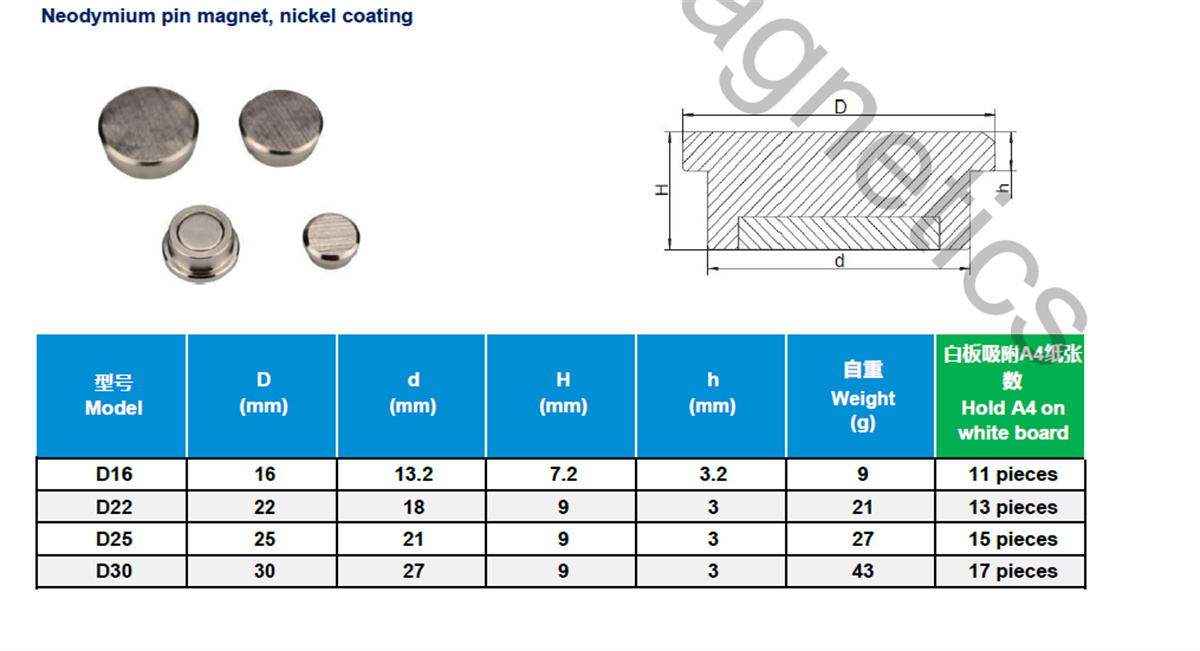

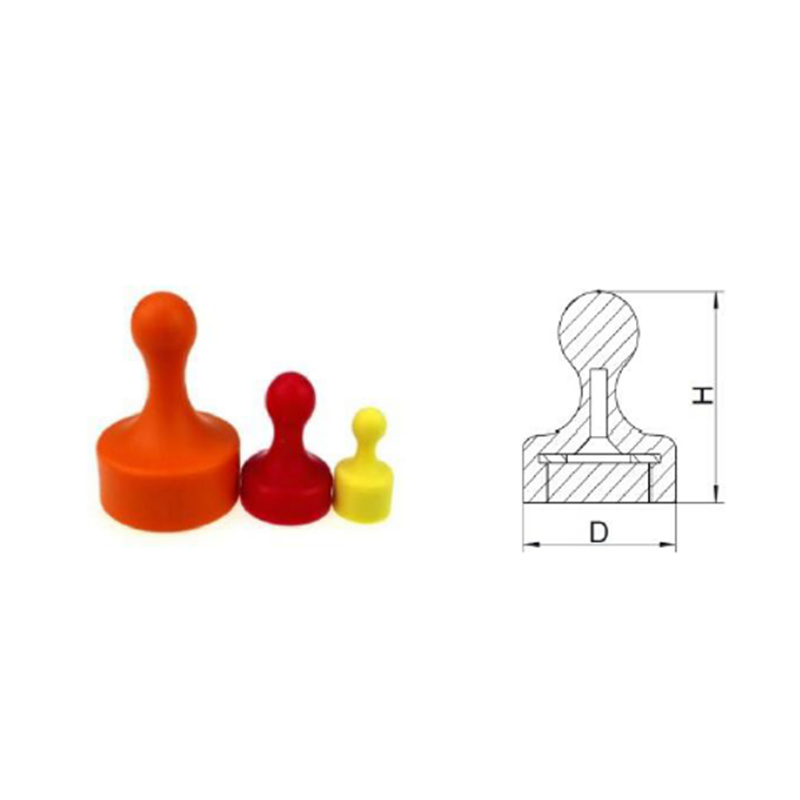

Neodymium Pin Magnet – Plastic or Nickel coating

Key Features

- Strong Neodymium Core: At the heart of each pin is a potent neodymium magnet, providing an unexpectedly strong hold for their compact size.

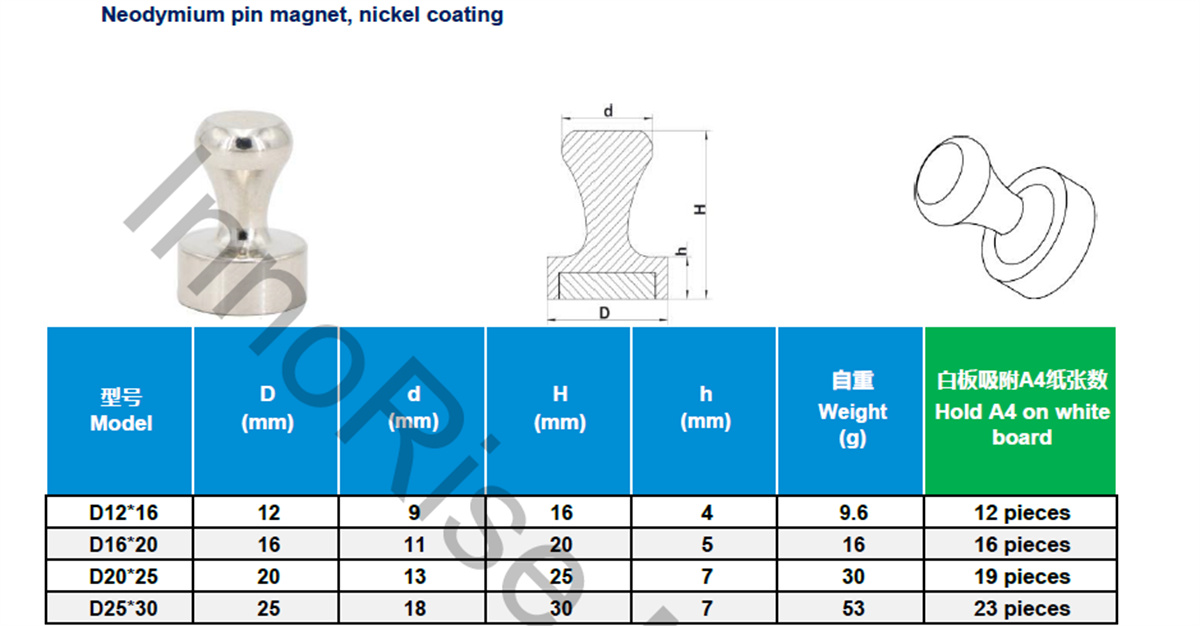

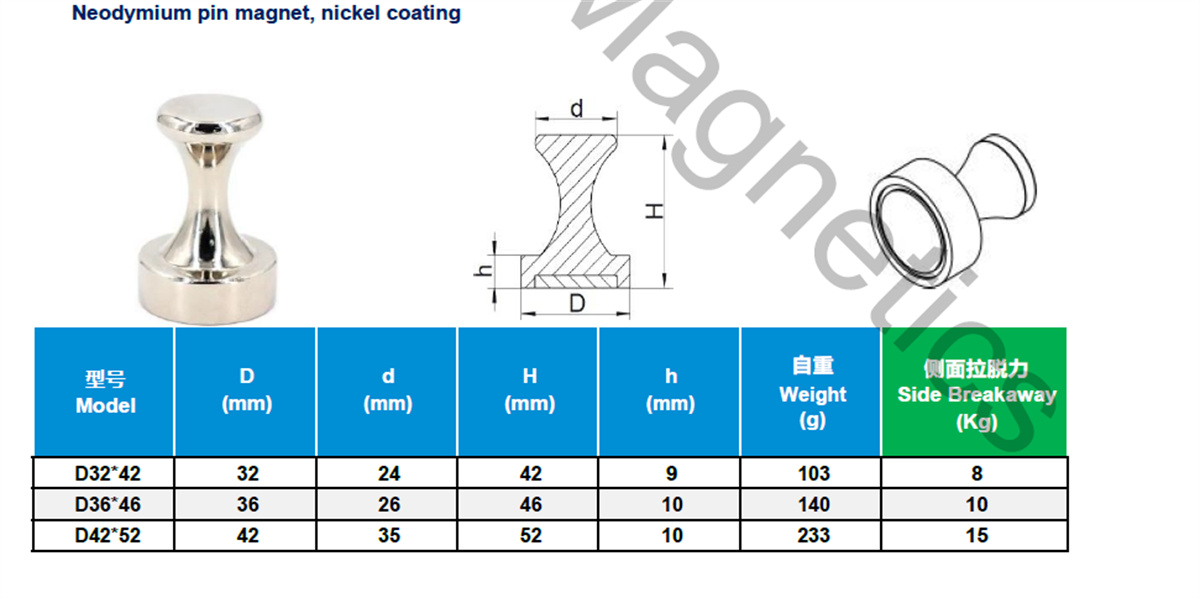

- Elegant Metallic Finish: Available in a classic silver color, these magnets are as stylish as they are practical, suitable for both professional and personal environments.

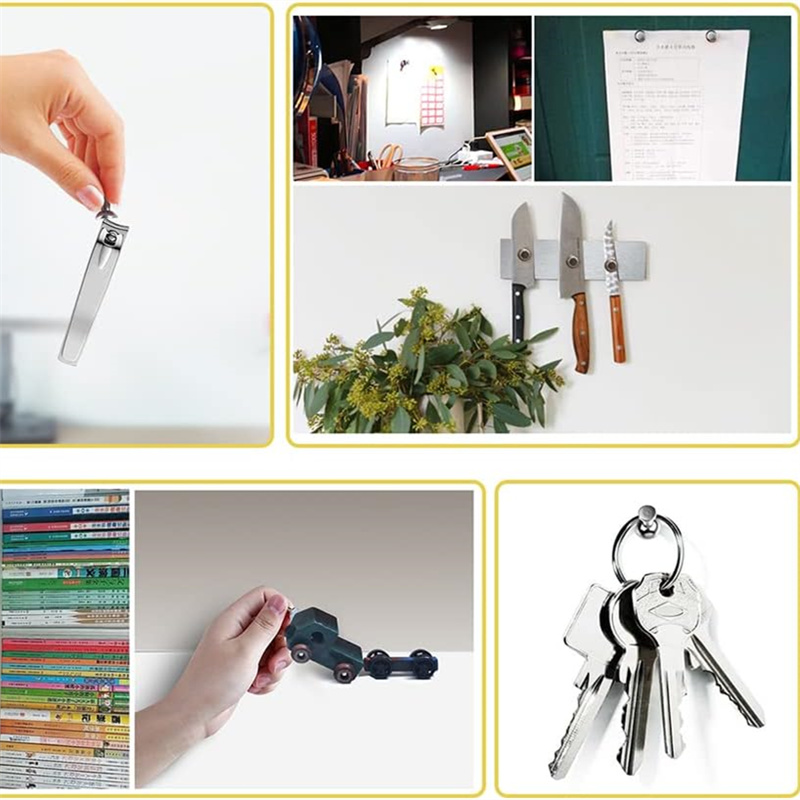

- Versatile Applications: Perfect for use on refrigerators, whiteboards, office cabinets, and magnetic maps, these magnets can securely hold papers, photos, and notes.

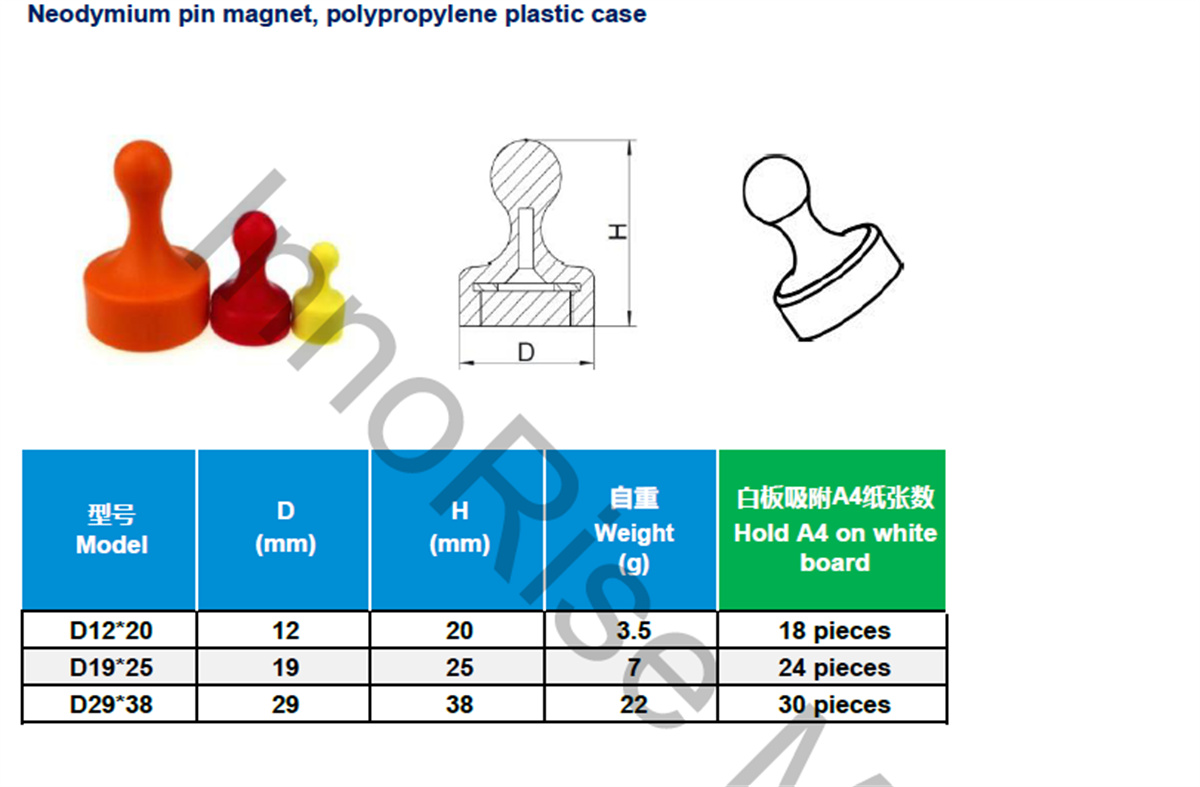

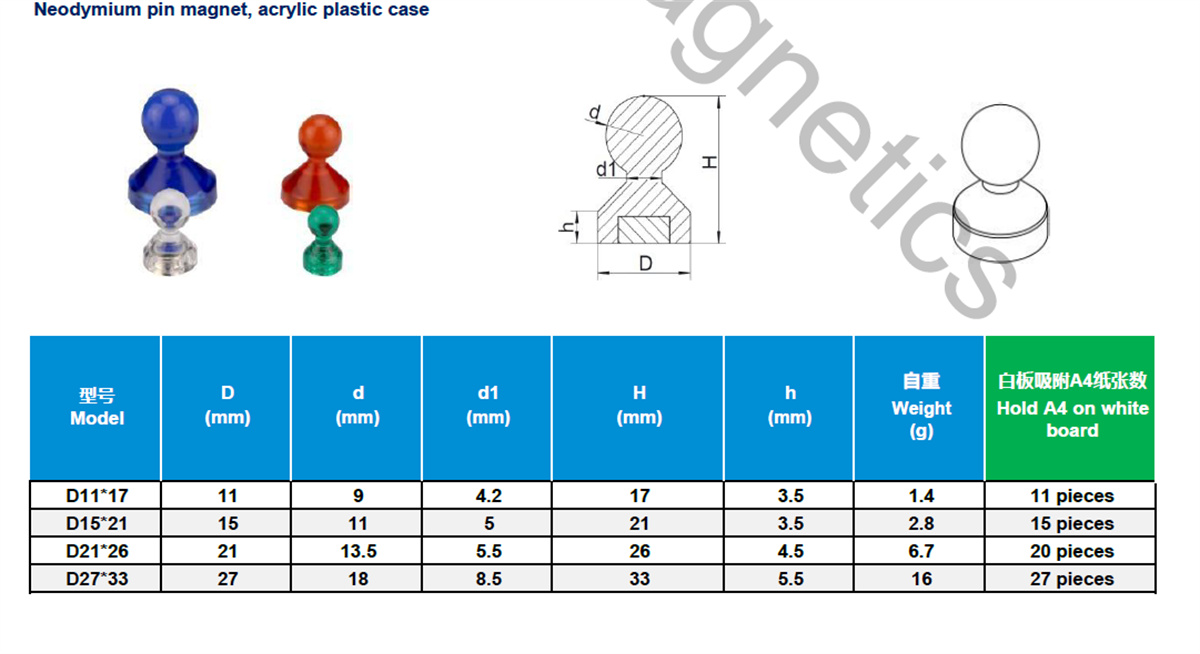

- Protective Coatings: Choose between a durable plastic casing for a colorful touch or a sophisticated nickel coating for enhanced durability and a premium feel.

- Compact and Convenient: These small yet powerful magnets are easy to handle and move, making them ideal for everyday use.

Applications

- Fridge Magnets: Keep your kitchen organized by holding up grocery lists, recipes, or family photos.

- Office Magnets: Ideal for holding documents on whiteboards or filing cabinets in the workplace.

- Whiteboard Magnets: Perfect for educational settings, allowing teachers and students to attach notices or educational material.

- Map Magnets: Use them to mark locations on magnetic maps, useful for planning trips or educational purposes.

Whether you’re looking to enhance your office’s organization, add a practical touch to your home, or just need a reliable way to display information, our Neodymium Pin Magnets are up to the task. Their blend of strength, style, and versatility makes them an essential accessory in any setting.

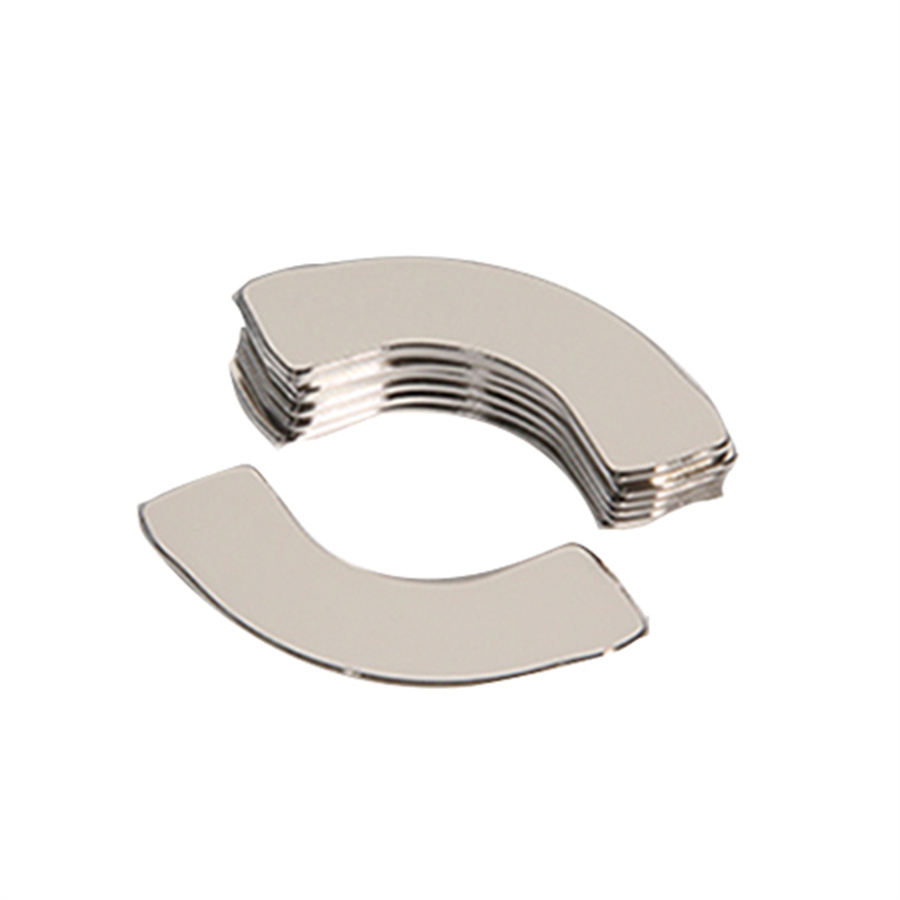

Production Process

1. Material preparation: Prepare NdFeB magnet material, plastic or metal shell material, and other materials needed for making magnetic needle.

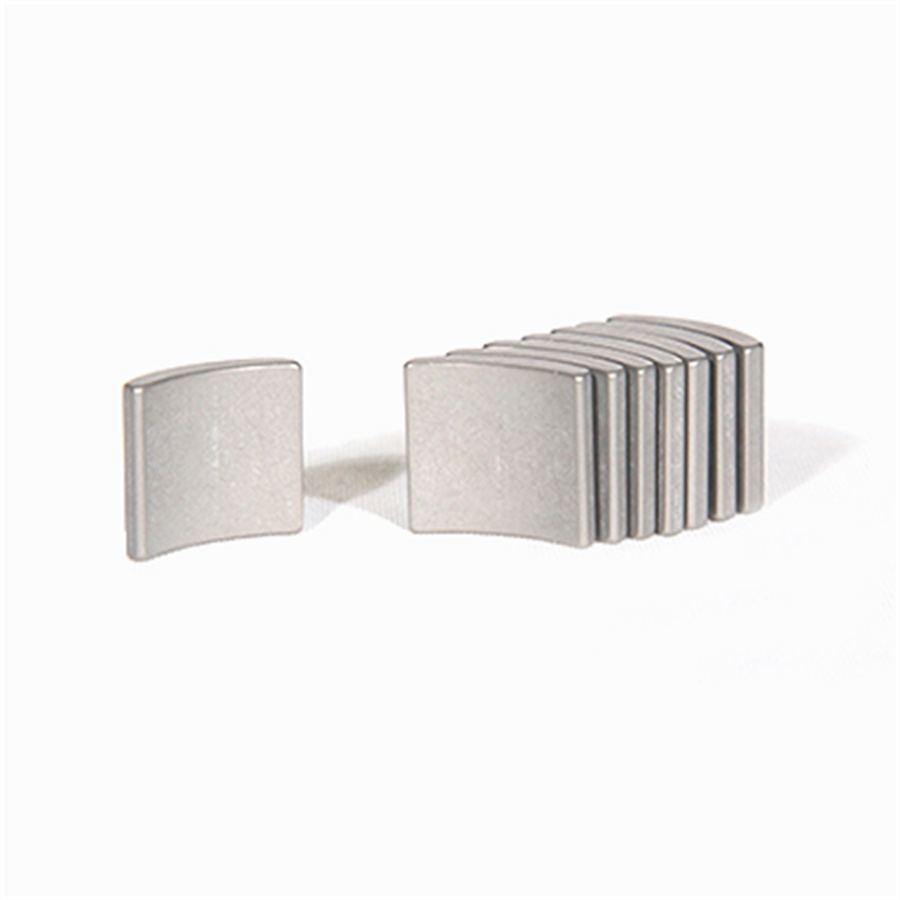

2. Cutting the magnet material: cut the NdFeB magnet material into small pieces of required size according to the design requirements.

3. Machining: Perform precision machining on the cut magnet material, including grinding, drilling and polishing, to ensure that its shape and size meet the requirements.

4. Assembly: The processed magnet material is put into the plastic or metal housing and the magnetic pin is fixed on the housing to form the Neodymium Pin Magnet.

5. Quality Inspection: Carry out quality inspection on the fabricated magnetic pins, including checking the appearance quality and magnetic properties.

6. Packaging: Packaging the magnetic pins that pass the quality inspection, ready for shipment or sale.